Fatal attraction for microplastics

This magnetic powder promises a faster method for removing microscopic pieces of plastic.

This magnetic powder promises a faster method for removing very small microplastics from waste water.

A new method for swiftly removing even the tiniest microplastics from water has been developed by researchers to protect the purity of rivers, lakes and oceans.

Microplastics are tiny plastic particles that present a significant ecological threat when released into the waterways via domestic and industrial wastewater.

As well as harming aquatic life, they allow harmful chemicals and toxins to enter the human food chain.

Researchers from Australia’s RMIT University say their powder-based solution aims to target the very tiny particles that have proved most challenging to detect for industrial operators such as waste water treatment plants.

Developing a cost-effective way to overcome these challenges is critical, lead researcher Professor Nicky Eshtiaghi says.

With millions of tonnes being released from homes and industrial plants into the sea every year, microplastic is not just harming ecosystems, but can also have a significant impact on human health.

Microplastics smaller than 5 millimetres can take up to 450 years to degrade, and are not detectable and removable through conventional treatment systems, the researchers say.

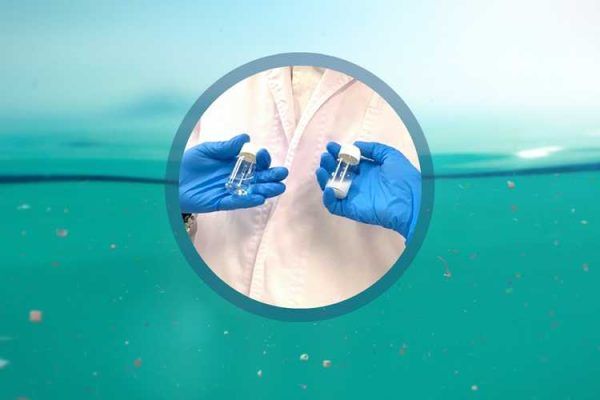

To target very small particles their powder-based solution acts as an ‘adsorbent’ that attracts microplastics and pollutants. It was developed using nanomaterials that can be mixed into water.

"The nano-pillar structure we’ve engineered to remove this pollution . . . is recycled from waste and can be used multiple times."

The adsorbent is enabled by the presence of iron within the ‘nanopillar’ that allows magnets to separate even very tiny microplastics and pollutants from the water, reducing a process that ordinarily takes days to just one hour.

“Our powder additive can remove microplastics that are 1,000 times smaller than those that are currently detectable by existing wastewater treatment plants,” Eshtiaghi says.

They also have the added benefit of being both cheap and sustainable.

“The nano-pillar structure we’ve engineered to remove this pollution, which is impossible to see but very harmful to the environment, is recycled from waste and can be used multiple times.

“This is a big win for the environment and the circular economy.”

As part of their research, Eshtiaghi and her colleagues have been working with Australian water utilities on an Australian Research Council Linkage project to optimise sludge pumping systems.

Following successful testing of the adsorbents in the lab, the researchers say they plan to approach other partners from industry to further develop their innovation.

“We are looking for industrial collaborators to take our invention to the next steps, where we will be looking at its application in wastewater treatment plants,” Eshtiaghi says.

The research results were published in the Chemical Engineering Journal.

The tech

To remove very tiny microplastics from water, RMIT researchers have developed a novel adsorbent in the form of a powder. These adsorbents have been created from nanomaterials that have iron incorporated into their structure to allow the team to use magnets to rapidly separate the microplastics and pollutants from the water within the space of an hour. According to researchers, the adsorbent’s special surface properties mean it can effectively and simultaneously remove both microplastics and dissolved pollutants from water. The solution has also been designed to work without creating any secondary pollutants or carbon footprints.

Who funds it

The RMIT researchers have successfully tested their adsorbents in the lab. They now plan to approach industrial partners involved in the task of removing microplastics from waterways.

Key players

Scientific and technical support was provided by RMIT’s Advanced Manufacturing Precinct. They also collaborated with water utilities in an Australian Research Council (ARC) Linkage project to optimise sludge pumping systems.